Behind the scenes: episode 3

Our laboratory is located in the heart of Paris. At Seasonly, we do not use white label formulas. We do not draw from laboratory catalogs already created formulas on which to affix our logo. We create our formulas from scratch and by relying on the expertise of our laboratory, recognized for its know-how in natural and clean cosmetics.

Step 1: the lab brief

We always start from customer insights; especially those that we collect in our Skin Studios and our Face Glow Bars. The goal ? Offer you the product(s) that may be missing from your bathroom.

Once the product concept is decided - the type of product and the desired texture, the appearance, the color sometimes, the smell, etc. - we begin to research ingredients to find those that would be most suitable . This is when we send the brief to our laboratory.

The challenge with our developments is that we formulate cleanly. Therefore, there are many ingredients that we cannot use. To develop a cream for example, we cannot formulate it with silicones. They are difficult to biodegrade and form an occlusive film on the skin (it should be noted, however, that for certain skin conditions, it is sometimes unavoidable to use them for this occlusive effect). We must then find alternatives to recreate this smoothing effect with a powder finish. In this case we use silica, a touch powder of natural origin.

The same goes for naturalness. To reach the minimum 95%, it sometimes takes us time to find the right ingredients in a formula. This is the case with vitamin C for example. One of our future products required more than a year of development to find the forms of vitamin C that would remain 95% natural while remaining stable.

Step 2: Submissions

We then receive submissions from our laboratory to test the formula. We pay particular attention to sensoriality, application, appearance of the product, effects, etc. And we especially have these submissions tested by people who present the targeted issues in order to have the most relevant feedback possible. .

During this development time, we start looking for packaging. We often reuse existing packaging in order to consolidate our orders and thus minimize our sourcing impact. This also allows us to have overall consistency between the packs and so that you can recognize us better!

Step 3: validation

Once the formula has been validated and the packaging found, our laboratory will conduct what is called a compatibility test. This makes it possible to verify that there is no interaction between the packaging and the formula. They will also carry out a stability test which consists of subjecting the product to accelerated aging in order to assess its integrity during storage. The product will be placed in an oven at a specific temperature for several weeks or months. During this period, samples will be taken to control the quality of the product in its final packaging.

We also need to do a patch test. This consists of applying the product to the skin, under an occlusive dressing, in order to detect any risk of intolerance or allergic reaction.

These are non-exhaustive examples: there are still many other tests such as the eye test (for products applied to the eye area or make-up removers for example), the safety test, etc...

Step 4: order

Once all the tests are good, you must place the order for packaging and raw materials.

For our part, while our laboratory takes care of gathering everything we need for production, we take care of the artwork. These are the decorations of our primary and secondary packaging; what will the product be called, what key information should be highlighted, etc.

Step 5: production

We are soon reaching the end of all our stages. The packaging has been screen printed, our secondary packaging has been printed and arrived at the factory, the raw materials have been checked: production can begin. Our factory in Belgium is launching what we call the "bulk". This is the production of our formula on a large scale, before moving on to packaging and putting it in a box.

Step 6: Launch

After several shootings, post-production and the creation of launch assets, we are ready to reveal our new product to you! So this is where you discover the product, after (very) many months.

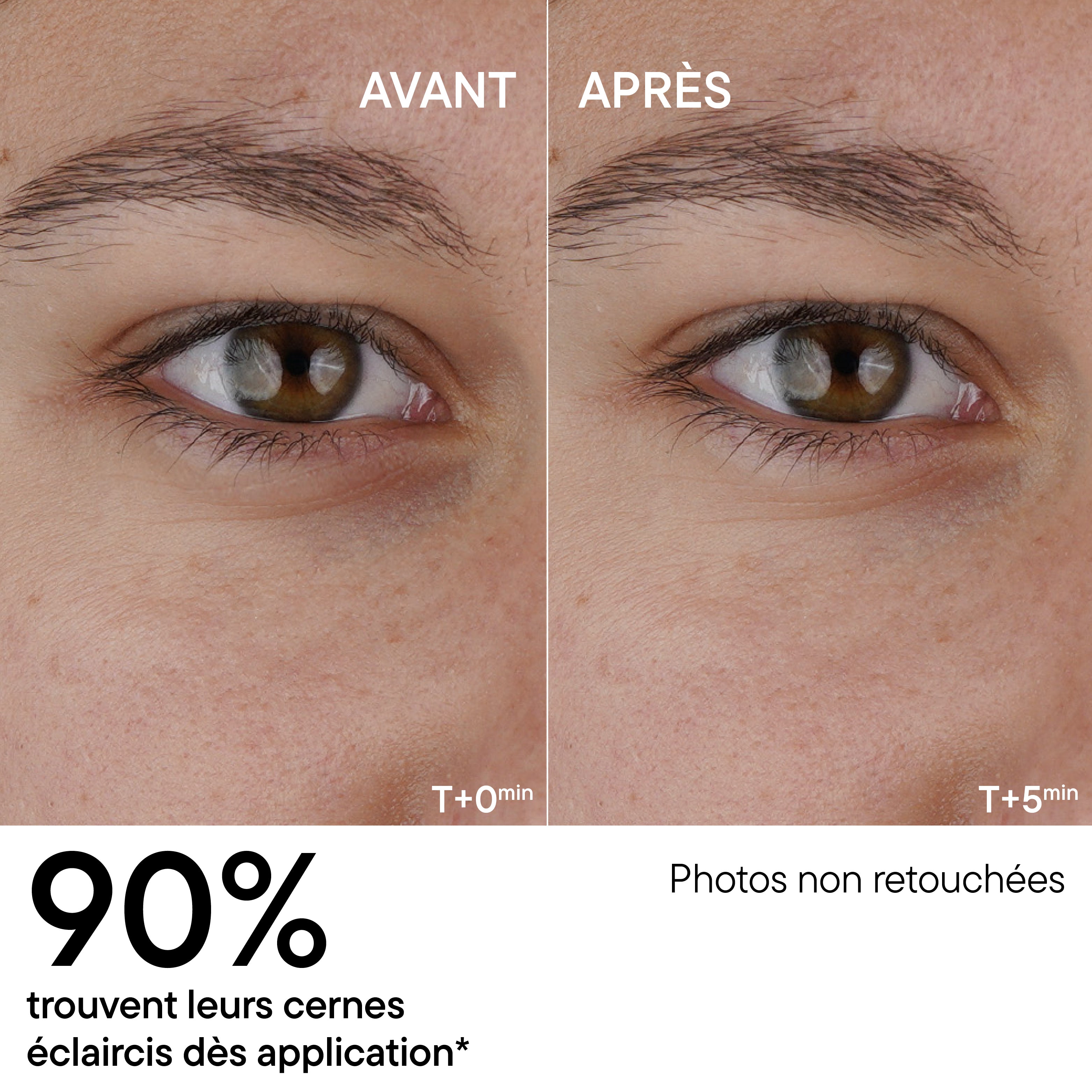

Our products have obviously also been tested with volunteers during so-called usage tests. It is thanks to this that we have the right to claim - or not - certain information about our products. For example: if we want to say that a particular product smoothes the skin texture, we must have at least 50% of our volunteers who find their skin texture smoothed after applying the product. We adapt the profiles of volunteers according to the product; for a product that targets imperfections, we will test them on people who have them, etc...

On certain products, we also carry out so-called “instrumental” tests. This time it is through the use of different measuring devices on voluntary subjects. This can be a test on wrinkles, on hydration, on elasticity, etc. We measure the parameter on D0 and we measure again later, either a few hours later, or 7 days later, etc. .. We decide! It is this test, for example, which allows us to say that we have +22% hydration on our fluid cream after 4 hours of application (see below).

All these tests are carried out under dermatological control by independent laboratories so, of course, that they are as objective as possible. On our upstream side, we also choose active ingredients for their proven effectiveness following this type of testing. These are very good indicators of the effectiveness of the product.

And there you have it, you know almost everything about the major stages of product development!